Features

●High accuracy and high stability

●Wide choice of measuring ranges

●Solid ceramic sensitive diaphragm

●Smart volume, easy for encapsulation

●Excellent shock and vibration resistance

●Excellent corrosion and abrasion resistance

●Low cost, extreme extensive application range

●Thermally compensated, wide-range operating temperature

Descriptions

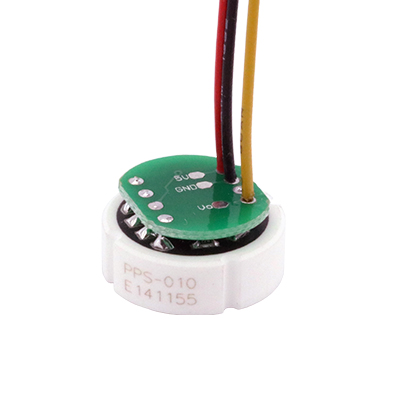

PS100E02 series 0-10V ceramic pressure sensor is made with ceramic cell (Al2O3 96%) and works following the piezoresistive principle. The signal conditioning electronics are mounted on one side of ceramic diaphragm where the wheatstone bridge is screen printed and offers 0-10V, 0-5V various voltage output signal.

PS100E02 series is fully temperature compensated and guarantees a residual temperature effect inside the compensation temperature range within 0.02%F.S./°C. This feature results in a very stable sensor under very harsh conditions. Thanks to the excellent chemical immunity of the ceramic material, the sensor is suitable for nearly all most media.

Mounting recommendations

The sensor is sensitive to the humidity, here is some recommendations for mounting. Before mounting, put the sensor into a drying oven with 85°C for at least 30 minutes. During mounting, make sure the environment humidity is keep under 50%. After mounting, appropriate sealing measures should be taken to protect the sensor.

|

Rated pressure |

2 |

5 |

10 |

20 |

30 |

50 |

100 |

200 |

400 |

|

Over pressure |

4 |

10 |

20 |

40 |

60 |

100 |

200 |

400 |

600 |

|

Burst pressure |

7 |

15 |

35 |

70 |

90 |

150 |

250 |

450 |

600 |

|

Accuracy |

±1.5% F.S. |

±1.0% F.S. |

±1.5% F.S. |

||||||

Low cost submersible pressure sensor

Low cost submersible pressure sensor

Waterproof IP68 pressure transducer

Waterproof IP68 pressure transducer

Low cost OEM level transmitter

Low cost OEM level transmitter

Flush pressure sensor

Flush pressure sensor

Sanitary pressure sensor

Sanitary pressure sensor

4-20mA piezoresistive pressure sensor

4-20mA piezoresistive pressure sensor

Flush pressure sensor for slurry, cement, crude oil

Flush pressure sensor for slurry, cement, crude oil

Piezoresistive differential pressure sensor

Piezoresistive differential pressure sensor

Low cost ceramic pressure sensor

Low cost ceramic pressure sensor

Isolated industrial pressure transmitter

Isolated industrial pressure transmitter

OEM pressure transmitter

OEM pressure transmitter

High temperature pressure sensor

High temperature pressure sensor

Industrial pressure sensor

Industrial pressure sensor

Piezoresistive pressure transmitter

Piezoresistive pressure transmitter

Stainless steel pressure sensor

Stainless steel pressure sensor

Oil pressure sensor

Oil pressure sensor

Refrigeration pressure sensor

Refrigeration pressure sensor

Low cost pressure sensor

Low cost pressure sensor

4-20mA ceramic pressure sensor

4-20mA ceramic pressure sensor

0-10V ceramic pressure sensor

0-10V ceramic pressure sensor

0.5-4.5V ceramic pressure transmitter

0.5-4.5V ceramic pressure transmitter

Industrial pressure transmitter

Industrial pressure transmitter

Miniature flush pressure transducer

Miniature flush pressure transducer

4-20mA low cost pressure transmitter

4-20mA low cost pressure transmitter

Industrial pressure transducer

Industrial pressure transducer

Flush diaphragm pressure transmitter

Flush diaphragm pressure transmitter

Flush mount pressure sensor

Flush mount pressure sensor

3.3 V pressure sensor

3.3 V pressure sensor

3.3 volt flush diaphragm pressure transmitter

3.3 volt flush diaphragm pressure transmitter

3.3V Submersible level sensor

3.3V Submersible level sensor

Low pressure transducer

Low pressure transducer

Piezoresistive pressure transmitters for hot steam application

Piezoresistive pressure transmitters for hot steam application

Flange type pressure transmitters

Flange type pressure transmitters

Semi flush diaphragm pressure transmitters

Semi flush diaphragm pressure transmitters

Tri-Clamp fitting pressure sensors

Tri-Clamp fitting pressure sensors

0-20mA piezoresistive pressure transmitters

0-20mA piezoresistive pressure transmitters