Features

● CE conformity

● Reverse polarity protection

● Stainless steel 316L wetted parts

● Silicone oil filled, rugged construction

● Wide measuring range: 0-0.1 bar to 1000 bar

● Output signals: 4-20mA or 0-10V, 0-5V, 0.5-4.5V

● A wide range of pressure and electrical connections

Descriptions

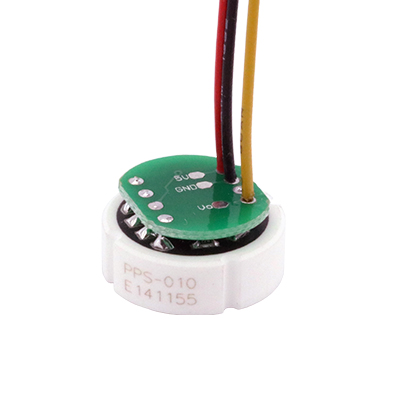

SS402 series flush pressure sensor is an oil-filled silicone sensor designed by the piezoresistive technology, works following the piezoresistive effect, pressure applied by the process media is hydraulically transmitted from the flexible diaphragm, through the filled fluid between the diaphragm and the instrument, to the pressure element. It is very rugged and robust, flush port connection with material of stainless steel 316L, has a ring on the diaphragm, offers excellent long term and stable performance throughout the complete range of pressures spanning from 0.1 bar up to 1000 bar with amplified voltage or current outputs.

SS402 series is highly configurable, with a variety of electrical termination and flush pressure port configurations, the sensor is ideal used in food process and industrial applications to measure the liquid and gas pressures, where the media is either viscous, or is otherwise liable to block the port of a conventional pressure transducer with a recessed diaphragm or pressure port.

Low cost submersible pressure sensor

Low cost submersible pressure sensor

Waterproof IP68 pressure transducer

Waterproof IP68 pressure transducer

Low cost OEM level transmitter

Low cost OEM level transmitter

Flush pressure sensor

Flush pressure sensor

Sanitary pressure sensor

Sanitary pressure sensor

4-20mA piezoresistive pressure sensor

4-20mA piezoresistive pressure sensor

Flush pressure sensor for slurry, cement, crude oil

Flush pressure sensor for slurry, cement, crude oil

Piezoresistive differential pressure sensor

Piezoresistive differential pressure sensor

Low cost ceramic pressure sensor

Low cost ceramic pressure sensor

Isolated industrial pressure transmitter

Isolated industrial pressure transmitter

OEM pressure transmitter

OEM pressure transmitter

High temperature pressure sensor

High temperature pressure sensor

Industrial pressure sensor

Industrial pressure sensor

Piezoresistive pressure transmitter

Piezoresistive pressure transmitter

Stainless steel pressure sensor

Stainless steel pressure sensor

Oil pressure sensor

Oil pressure sensor

Refrigeration pressure sensor

Refrigeration pressure sensor

Low cost pressure sensor

Low cost pressure sensor

4-20mA ceramic pressure sensor

4-20mA ceramic pressure sensor

0-10V ceramic pressure sensor

0-10V ceramic pressure sensor

0.5-4.5V ceramic pressure transmitter

0.5-4.5V ceramic pressure transmitter

Industrial pressure transmitter

Industrial pressure transmitter

Miniature flush pressure transducer

Miniature flush pressure transducer

4-20mA low cost pressure transmitter

4-20mA low cost pressure transmitter

Industrial pressure transducer

Industrial pressure transducer

Flush diaphragm pressure transmitter

Flush diaphragm pressure transmitter

Flush mount pressure sensor

Flush mount pressure sensor

3.3 V pressure sensor

3.3 V pressure sensor

3.3 volt flush diaphragm pressure transmitter

3.3 volt flush diaphragm pressure transmitter

3.3V Submersible level sensor

3.3V Submersible level sensor

Low pressure transducer

Low pressure transducer

Piezoresistive pressure transmitters for hot steam application

Piezoresistive pressure transmitters for hot steam application

Flange type pressure transmitters

Flange type pressure transmitters

Semi flush diaphragm pressure transmitters

Semi flush diaphragm pressure transmitters

Tri-Clamp fitting pressure sensors

Tri-Clamp fitting pressure sensors

0-20mA piezoresistive pressure transmitters

0-20mA piezoresistive pressure transmitters